Production year

2017

© Jean-Claude MOSCHETTI / IRCER / CNRS Images

20170068_0049

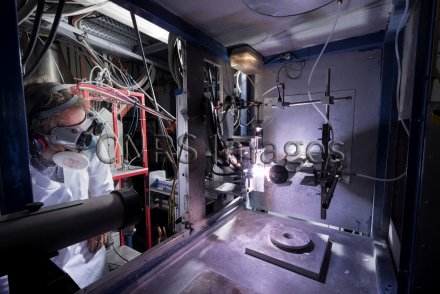

Plasma projection of ceramic material for the generation of thermal barriers. Plasma projection is used to apply ceramic coatings to the turbine vanes in the combustion chamber of jet plane engines, for example, to prevent corrosion, oxidation and thermal stresses. In addition, sand or dust present on runways, or in volcanic ash in the event of a volcanic eruption, can enter the turbines and melt at 1200°C, causing the thermal barriers to crack when the engine cools. The thermal barrier comprises yttria-stabilised zirconia, on the outside, followed by an alumina layer referred to as a "TGO" created from a metal undercoat deposited onto the metal superalloy from which the vane is made. The gas (argon, hydrogen and helium) that projects the suspension onto the substrate becomes a plasma, i.e. an ionised gas, as it crosses an electric arc in permanent short-circuit and exceeds a temperature of 6000°C. The speed of impact of the particles on the substrate is between 200 and 400 m/s. The layer deposited is 100 - 500 microns thick, while the distance between the torch and the substrate is 60 mm.

The use of media visible on the CNRS Images Platform can be granted on request. Any reproduction or representation is forbidden without prior authorization from CNRS Images (except for resources under Creative Commons license).

No modification of an image may be made without the prior consent of CNRS Images.

No use of an image for advertising purposes or distribution to a third party may be made without the prior agreement of CNRS Images.

For more information, please consult our general conditions

2017

Our work is guided by the way scientists question the world around them and we translate their research into images to help people to understand the world better and to awaken their curiosity and wonderment.